Flow Battery - Energy Storage System/BMS

Classification:Company News

- Author:ZH Energy

- Release time:Jul-04-2025

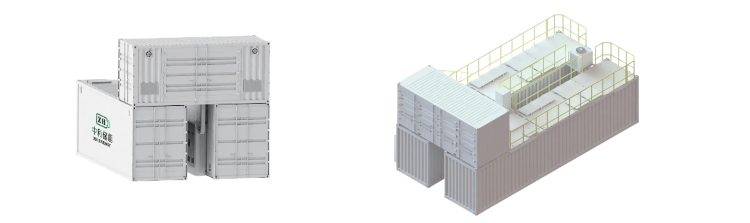

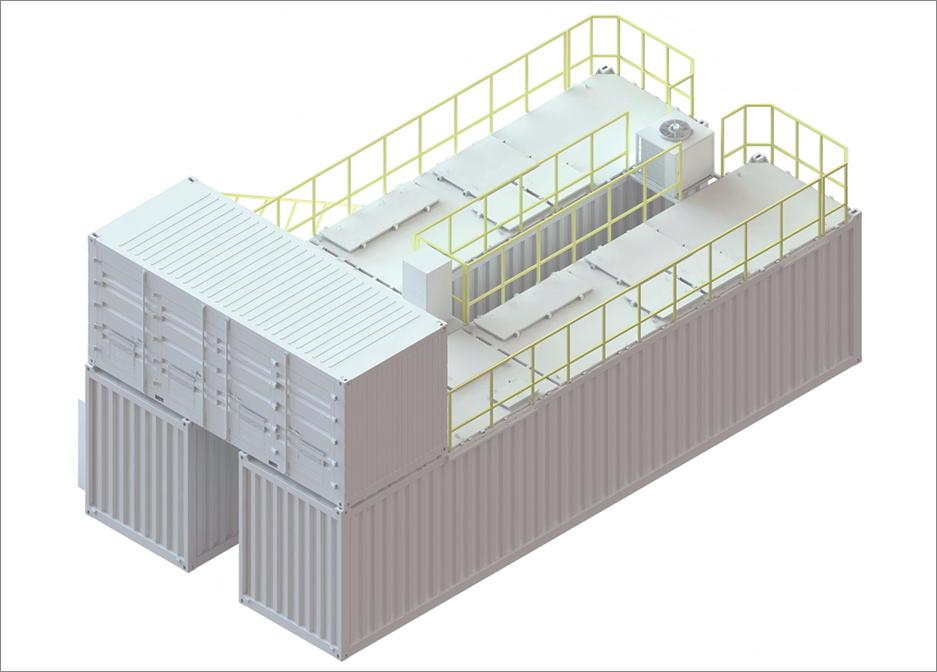

【 Summary 】ZH Energy 's standardized all-vanadium flow battery modules have reached the 375kW level. It has successfully delivered multiple megawatt-level projects both domestically and internationally, and has the capability for mass production and operation and maintenance of large-scale energy storage projects.

1、 Vanadium Redox Flow Battery and Sulfur Iron Flow Battery Energy Storage Systems

ZH Energy relying on the founder Dr. Xie Wei's more than ten years of industrial experience in the US flow battery industry, has successfully developed a new type of flow cell stack with international leading level and built a cell stack production line with an annual capacity of 100MW. It has established a complete R&D and manufacturing system covering both vanadium and sulfur iron technology routes. The company's vanadium flow battery standard modules have reached the 375kW level and have successfully delivered multiple megawatt-level projects both domestically and internationally. It has the capability for mass production and operation and maintenance of large-scale energy storage projects, verifying its strength in technological engineering and commercialization.

Aiming at the pain points of high installation cost and resource limitations of vanadium flow batteries, ZH Energy has jointly developed the next-generation low-cost sulfur iron flow battery with Central South University. Compared with vanadium batteries, the electrolyte cost can be significantly reduced by 85%, becoming an economical and safe large-scale energy storage technology. As a pioneer in the commercial application of sulfur iron batteries globally, the company has successfully connected the world's first sulfur iron flow battery verification project jointly built with the State Grid to the grid. The performance has reached the world's leading level. It is currently preparing for the construction of the first megawatt-level sulfur iron flow battery demonstration project in China and is expected to launch commercial engineering products in 2026.

Features:

- High safety, no risk of combustion and explosion. Vanadium flow batteries use aqueous electrolytes, which are non-flammable and have no risk of high-temperature expansion and deformation. They are an intrinsically safe electrochemical energy storage technology and can replace lithium batteries in applications with high safety requirements.

- Electrolyte does not degrade, long service life. Vanadium flow batteries use the change in the oxidation state of vanadium ions for energy storage. There are no physical processes of ion intercalation and deintercalation, and no precipitation or gas phase change phenomena. Therefore, vanadium electrolyte is very stable, with a theoretical life that can reach infinity. The system's service life can reach more than 20 years and can match the operating years of photovoltaic and wind power generation facilities.

- Flexible configuration of power and capacity. The power unit and capacity unit of flow batteries are independent. The cell stack determines the power size, and the electrolyte determines the capacity. It can be designed according to customer's electricity demand and can also be flexibly expanded in the future according to the electricity situation.

- Long continuous power supply time. By increasing the amount of electrolyte, the power supply time can be extended to 4-8 hours, which can play the role of peak shaving and valley filling and reducing capacity demand. Under the two-part tariff rule, it can obtain both peak-valley arbitrage and capacity reduction benefits.

Application Scenarios:

- Industrial and commercial energy storage for peak-valley arbitrage and capacity tariff savings

- Peak and frequency regulation for wind and photovoltaic power stations

- Integrated photovoltaic energy storage and charging solutions for highway service areas

- Frequency regulation, ramping and other ancillary services on the power generation side and distribution side

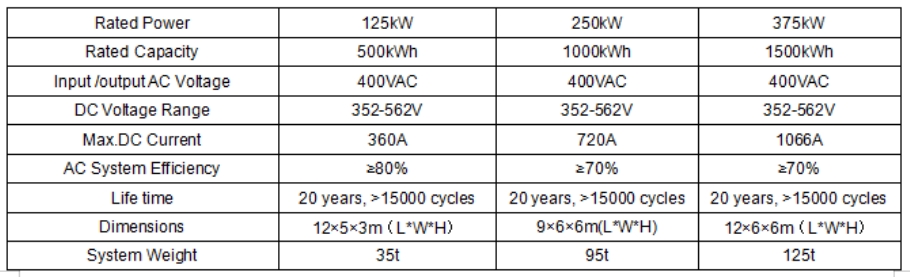

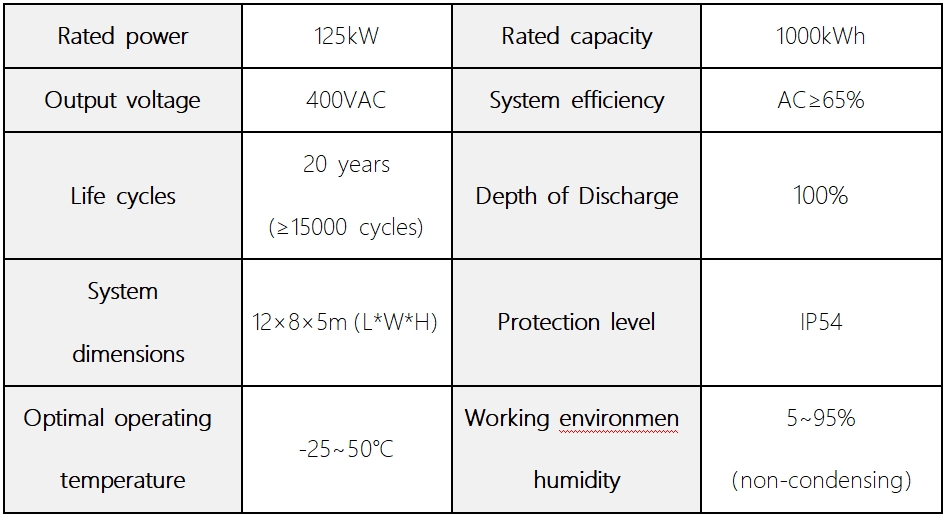

Specifications

Note: Standardized energy storage system, can be used independently or connected in series and parallel to form a large energy storage station. In addition to containerized systems, there are also tank-type systems. For details, please contact for consultation.

Features

- Wide raw material sources and controllable costs. Sulfur iron flow batteries use sulfides and complex iron compounds to prepare electrolytes. The raw materials are large-scale chemical raw materials with low prices and are not easily affected by supply and demand to produce drastic changes.

- Full liquid electrolyte, stable chemical structure, no degradation, long service life. Sulfur iron flow batteries use the chemical valence changes of sulfur and iron elements for energy storage. There are no physical changes of ion intercalation and deintercalation, no metal solid or gas phase transitions, and the inorganic compound structure is stable and non-degradable. Therefore, the electrolyte is very stable, with a service life of up to 20 years, matching the operating years of photovoltaic and wind power generation facilities.

- Stable molecular structure at high temperatures, no temperature control system required. Sulfur iron electrolyte does not precipitate at high temperatures and has better reaction activity. Therefore, no high-temperature cooling system is needed, which can save both system costs and operating energy consumption. Compared with lithium batteries and vanadium batteries, it is more suitable for application needs in high-temperature areas.

- Long continuous power supply time. Due to the low cost of electrolyte, the marginal cost of sulfur iron flow batteries is very low, and the cost advantage is more obvious in systems with longer discharge time. It is suitable for intra-day 6-12 hour energy storage applications.

Application Scenarios

- Industrial and commercial energy storage for peak-valley arbitrage and capacity tariff savings

- Peak and frequency regulation for wind and photovoltaic power stations

- Large-scale independent shared energy storage station

Specifications

The Flow Battery Management System (FBMS) independently designed and developed by ZH Energy covers all monitoring, calculation and control functions of the flow battery system. It can monitor the temperature, pressure and SOC of the electrolyte in real time, and accurately control the flow and pressure of the electrolyte. It can monitor the state of the electrolyte in real time, display fault information and issue warnings. It supports communication with the EMS system. It can flexibly adapt to different flow battery technology routes and their unique parameters, and provides a function for customizing system parameters. It can be customized and produced according to customer needs.

Features

- Comprehensive functions: covering all monitoring, calculation and control functions of the flow battery system.

- Easy operation: all operations can be completed through the built-in touch screen, and data interaction and instruction transmission with the EMS system are also possible.

- Flexible use: applicable to various flow battery technologies, providing a function for customizing system parameters, which can be set according to the customer's system situation.

- Good scalability: with independent intellectual property rights, it can be customized and produced according to customer needs.

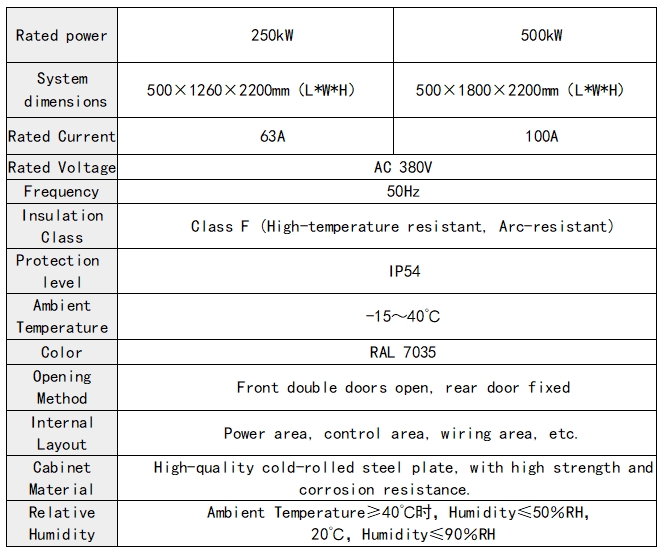

Specifications

Note: More specifications can be customized according to actual needs.

Product Series:

Flow Battery Test Platform