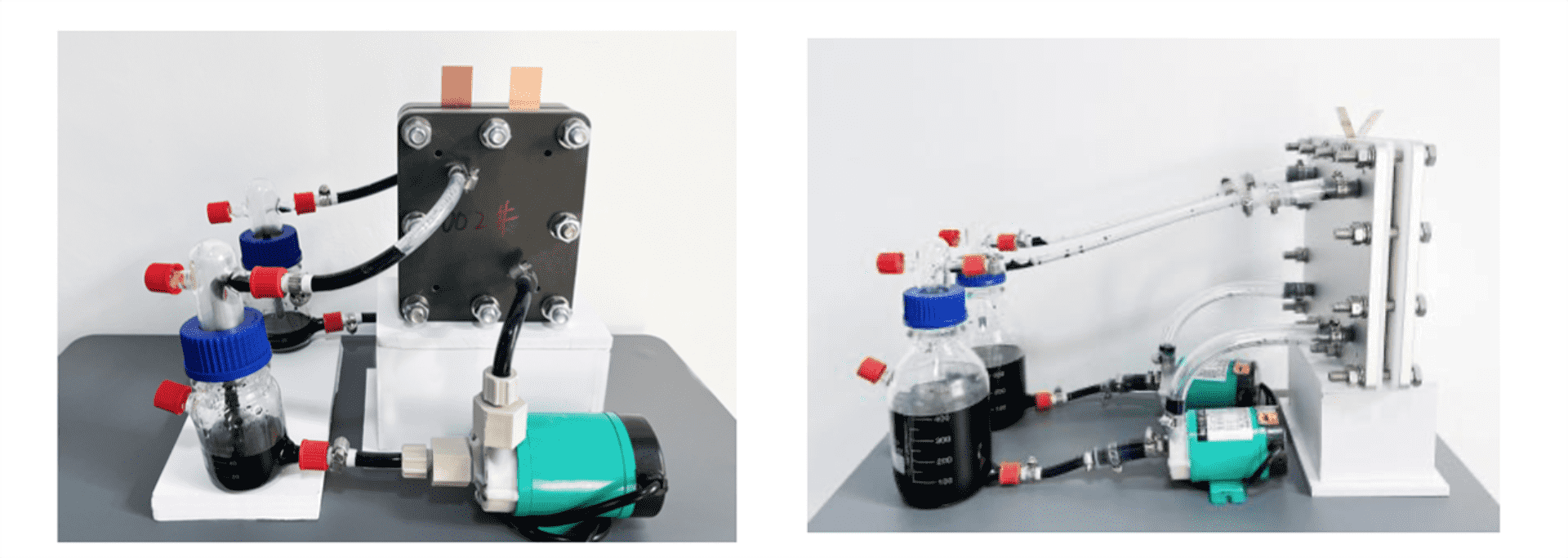

3W、20W Single-cell System

The Laboratory product series includes: single-cell systems, laboratory stacks, and laboratory systems, which are suitable for universities, research institutions, and manufacturers to conduct various research on flow batteries.

Product Features:

The structure is simple, easy to assemble and disassemble, and meets the laboratory's frequent requirements for disassembly and testing.

The flow channel has been optimized, resulting in improved efficiency. Compared to designs without flow channels, the energy efficiency of individual cells is significantly enhanced.

Available in various specifications, it can meet the experimental needs of different power levels.

The system contains: a single-cell battery (clamp, current collectors, frame,bipolar plates, proton exchange membrane, graphite felt electrode), twoelectrolyte tanks, two electrolyte pumps, and electrolyte pipelines.

| Product specifications | ||

|---|---|---|

| Rated power | 3W | 20W |

| Electrolyte flow rate | >50 mL/min | >250 mL/min |

| Battery size | 12×15×7cm3 | 20×22×7cm3 |

| Effective area | 4cm×4cm | 12.5cm×8cm |

| Voltage range | DC:0.8—1.6V | |

| Energy efficiency | DC≥80% | |

| low field design | in the plastic frame | |

| Test temperature | 25±5℃ | |

| Number of electrolyte ports | 4(inlets and outlets on the same side) | |

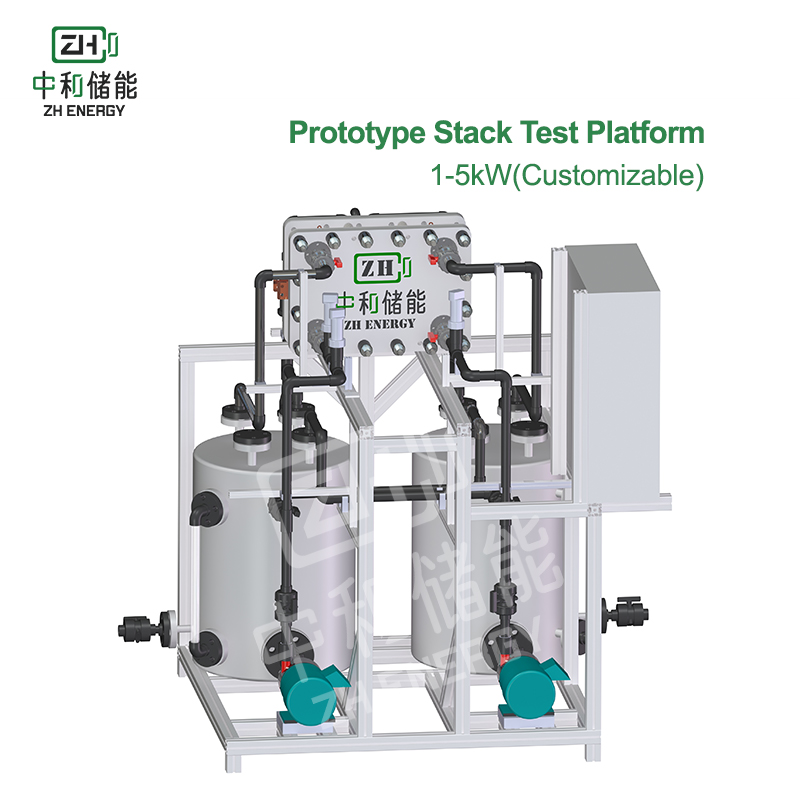

Flow Battery Test Platform

PRODUCT OVERVIEW

The flow battery test platform is fully functional and contains a variety of monitoring sensors to meet various material or process testing requirements. The platform adopts modular design, easy disassembly and assembly, and is suitable for research institutions and manufacturers to test flow battery materials, stacks or systems.

PRODUCT FEATURES

Good Repeatability: Simple structure , easy to disassemble and move, and can meet the experimental needs of frequent disassembly;

Good Consistency: The modular design ensures standardized assembly and the production process has been certified by ISO9001 International Quality Management System;

Diverse Specifications: small platforms can meet the testing needs of 1-5kW/2h, while large platforms can meet the testing needs of 10-50kW/2h, and can be customized according to customer needs.

SPECIFICATIONS

Small stack test platform standard version (1kW, 5kW)

System includes: stack(optional), electrolyte tank, electrolyte pump, transmission pipeline, sensor, electric control cabinet, etc

| Product specifications | |||

|---|---|---|---|

| 1kW/2h | 5kW/2h | ||

| Rated power | 1kW | 5kW | |

| Rated capacity | 2kWh | 10kWh | |

| Voltage range | 10-16V | 50-80V | |

| Max Current | 112A | ||

| System efficiency | DC≥80% | ||

| Cycle index | ≥15000 | ||

| System dimension | 1.2×1.2×1.0m(W*D*H) | ||

| Weight | 1T | ||

| IP Grade | IP20 | ||

| Optimum Operating Temperature | 20-40 ℃ | ||

| Humidity | 5-95%(Non-condensate) | ||

Big stack test platform standard version (32kW, 42kW)

System includes:stack (optional), electrolyte tank, electrolyte pump, transmission pipeline, sensor, electric control cabinet, BMS (optional), etc

| Product specifications | |||

|---|---|---|---|

| 32kW/2h | 42kW/2h | ||

| Rated power | 32kW | 42kW | |

| Rated capacity | 64kWh | 84kWh | |

| Voltage range | 10-16V | 50-80V | |

| Max Current | 364A | 584A | |

| System efficiency | DC≥80% | ||

| Cycle index | ≥15000 | ||

| System dimension | 4.5×2.5×2.0m(W*D*H) | ||

| Weight | 2T | ||

| IP Grade | IP20 | ||

| Optimum Operating Temperature | 20-40 ℃ | ||

| Humidity | 5-95%(Non-condensate) | ||