Vanadium Electrolyte Electrolysis Production Line

PRODUCT OVERVIEW

As the "blood" of the all-vanadium redox flow battery (VRFB), vanadium electrolyte is the core material that determines the performance, lifespan, and cost of its energy storage system. Our vanadium electrolyte electrolysis production line, with high purity, long lifespan, and low cost as its core competitive advantages, is dedicated to providing global customers with large-scale, intelligent electrolyte production services. We aim to supply high-performance electrolytes for the global long-duration energy storage market, supporting the energy transition and the achievement of carbon neutrality goals. To date, we have successfully delivered multiple sets of products both domestically and internationally, achieving our capacity targets and ensuring stable operation.

PRODUCT FEATURES

Intelligent and efficient: Full-process digital control with real-time monitoring of electrolyte and equipment status; capable of interacting with higher-level systems to enable unattended operation.Stable performance: Uses stacks specially designed for electrolyte electrolysis, featuring low energy consumption, no leakage, and low risk of sediment formation and flow channel blockage, ensuring stable operation throughout the designed service life. Precise control: Based on years of electrolyte production experience, optimized charging control strategies improve electrolysis speed while maintaining high energy efficiency and reducing power losses, enabling simple one-button production setup and operation. High scalability: Modular production line design supports customized expansion with an annual capacity ranging from 3,000 to 30,000 m³, adaptable to energy storage projects of different scales.

SPECIFICATION

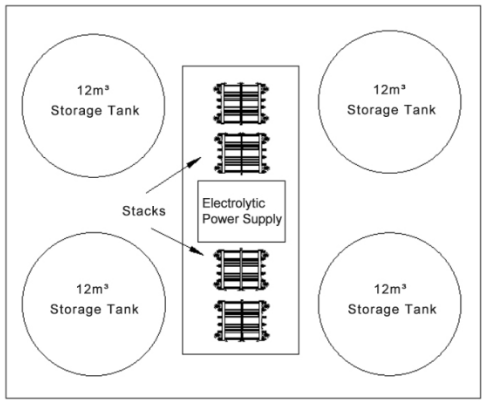

Standard Module: 10,000 m3/year The system consists of stacks, piping systems, pumps, storage tanks, a control and management system, and an electrolysis power supply. The system is divided into two independent subsystems. Each subsystem is equipped with two stacks, two storage tanks, and one set of piping and pumps. The stacks and pumping system are integrated into a 20-foot container. A shared dual-channel electrolysis power supply and electrical control cabinet are used, facilitating transportation and installation.

| Specifications | ||

|---|---|---|

| Structure | 20-foot container | |

| Production lines | 2, operating independently | |

| Annual capacity capacity | ≥10,000 m³(3 shifts/day, 250 days/year) | |

| Drive method | Circulation pump | |

| Sealing performance | Fully sealed, no external leakage | |

| Operating voltage | 0 – 300 V | |

| Operating current | 240 A, constant current operation | |

| Electrolytic power supply | 300V/300A dual-channel | |

| Protection rating | IP54 | |

DEPLOYED PROJECTS

| Customer: V-battery Energy Storage | Customer: Vessolyte |

| Deployed year: 2025 | Deployed year: 2025 |

| Production capacity: 5,000 m3 | Production capacity: 10,000 m3 |

|

|