Breaking Through the Pain Points of Organic Flow Batteries: Three Core Bottlenecks and a Full-Chain Solution

Classification:Industrial News

- Author:ZH Energy

- Release time:Oct-13-2025

【 Summary 】From molecular design in the lab to scaled-up application, modular and comprehensive testing tools empower the resolution of R&D challenges.

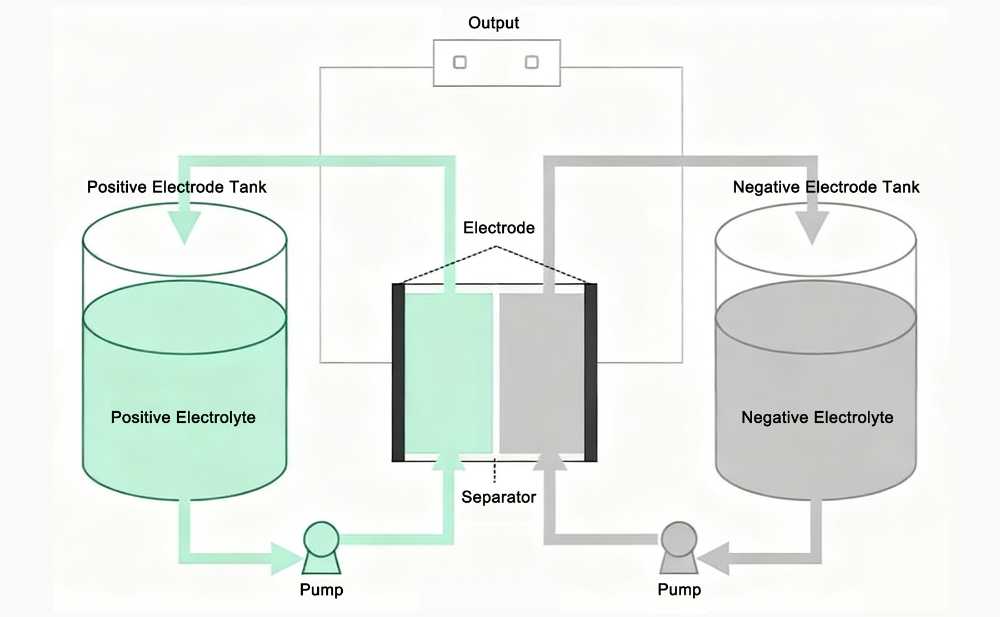

As the global energy transition accelerates, organic flow batteries (OFBs) have emerged as a promising new technology route following vanadium flow batteries, thanks to their advantages such as low cost, high safety, and molecular designability. Research interest in organic active materials—including quinoline derivatives, viologens, and TEMPO—has continued to rise; in 2025, the number of global patents related to OFBs increased by over 200% year-on-year. However, there are still three core bottlenecks in the transition from laboratory-based molecular design to large-scale application:

Molecular Stability Challenge: Organic active materials are prone to irreversible degradation (e.g., polymerization, decomposition) during long-term cycling, leading to rapid capacity fading.

Electrolyte-Material Compatibility Issue: High-concentration organic electrolytes are significantly more corrosive to separators and electrodes than traditional aqueous systems.

Engineering Scaling Gap: The excellent performance achieved in small-scale trials often drops sharply after stack integration, usually due to uneven mass transfer and intensified side reactions.

How to break through these bottlenecks? The key lies in "Precision R&D": establishing a full-chain research system covering the verification of intrinsic material properties, engineering scaling tests, and system integration evaluation to accelerate technology maturation.

Schematic Diagram of Organic Flow Batteries

I. Breakthrough Path via Collaborative Innovation in Materials and Engineering

1. Molecular Design and Material Verification

Optimization of Active Molecules: Functional group modification is used to balance solubility and redox reversibility. For example:

Introducing sulfonic acid groups into quinone derivatives can improve water solubility (e.g., AQDS reaches 1.5M), but side reactions need to be suppressed;

Nitrogen-site modification of viologen molecules enables potential regulation, yet the instability of their reduced state must be addressed.

Breakthroughs in Separator Materials: Traditional perfluorinated membranes (e.g., Nafion) face problems of cross-contamination and chemical degradation in organic systems. New microporous framework membranes (e.g., COFs) achieve precise sieving through rigid pores (<1nm), while zwitterionic membranes repel organic molecules using electrostatic forces.

2. Engineering Integration and System Optimization

Stack Design: To address the high viscosity of organic electrolytes (e.g., the viscosity of 2,6-DHAQ reaches 15cP), the adoption of 3D flow field design can improve mass transfer efficiency by 40%, and experimental verification of the adaptability of different flow fields is required.

System Management: High-viscosity electrolytes increase pumping energy consumption; meanwhile, some redox couples (e.g., flavin mononucleotide) react faster at high temperatures but may trigger side reactions, thus requiring a closed-loop temperature control system. For instance, Harvard University increased the energy efficiency of quinone-bromine batteries from 75% to 82% through temperature regulation.

It is urgent to establish a full-chain R&D system, ranging from the verification of intrinsic material properties (e.g., cycle stability, transmembrane permeability) to stack scaling tests (e.g., flow field optimization, sealing performance).

II. Multidisciplinary Integration Drives Industrialization

The maturation of organic flow batteries requires the integration of multiple disciplines such as computational chemistry, AI prediction, and bionic design:

AI-Assisted Screening: The California Institute of Technology used machine learning to screen 300 potential redox couples, shortening the experimental cycle by 70%;

Bionic Molecular Design: By drawing on the structure of biological redox enzymes (e.g., cytochromes), the molecular stability and reaction efficiency are improved.

III. Scientific Research Tools Accelerate OFB R&D

In response to the complex R&D needs of organic flow batteries, modular and full-chain testing tools have become the key to breakthroughs:

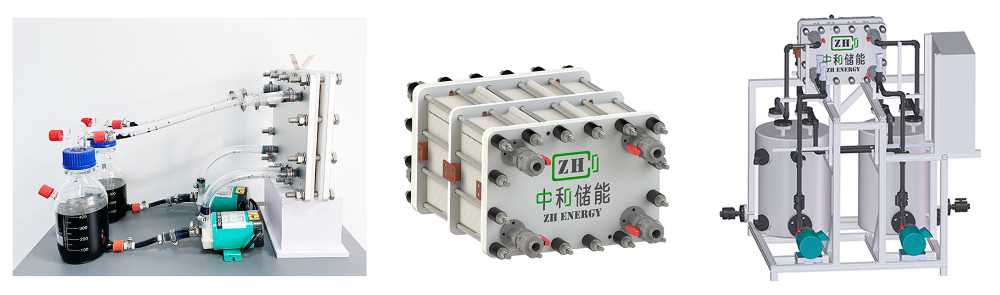

Single-Cell Testing System: Rapidly screens electrolyte formulations and membrane materials (e.g., evaluating the capacity fading rate after 100 cycles);

Pilot-Scale Stack Platform: Simulates the fluid behavior of MW-level systems to identify engineering problems;

System Verification Environment: Integrates modules such as thermal management and BMS (Battery Management System) to comprehensively evaluate commercialization indicators.

ZH Energy LAB series testing solutions are designed to build this R&D closed loop. We are committed to providing global OFB R&D teams with full-process data support, covering molecular design, material verification, stack optimization, and system evaluation, helping you transform innovative molecules into energy storage products with market competitiveness.

Legends for Single-Cell System, Pilot Stack, and Pilot System

With collaborative breakthroughs in materials and engineering technology, organic flow batteries are expected to open up differentiated tracks in fields such as distributed energy storage and user-side backup power. Every leap from the "beaker" to the "megawatt scale" requires precise data support and efficient verification tools. ZH Energy LAB series testing solutions have supported the research of multiple global OFB projects, providing full-process data empowerment from molecular design to system implementation.

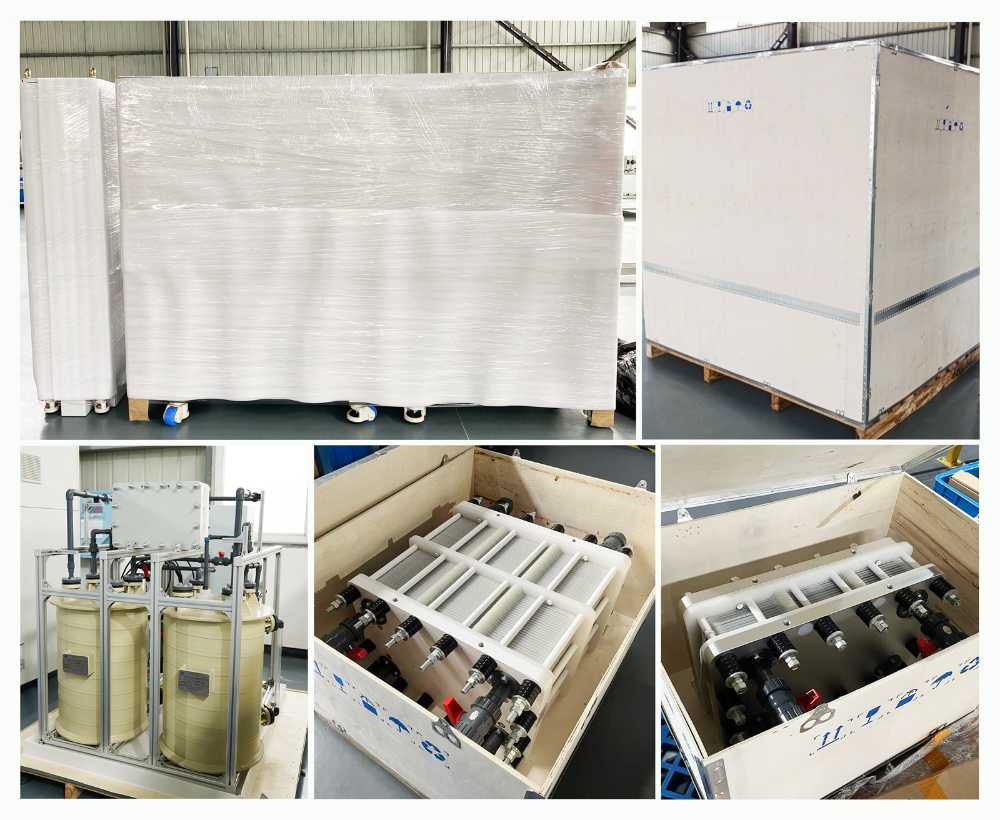

Organic Flow Battery Delivery Cases--Some cases are not publicly displayed temporarily due to confidentiality