Surpassing Nafion! 26× Proton-Conductivity Leap in PBI Membrane—Secret Unveiled & Mass Production Achieved

Classification:Company News

- Author:ZH Energy

- Release time:Aug-18-2025

【 Summary 】In this joint study, ZH Energy and Prof. Su-Qin Liu’s team at Central South University introduce a high-concentration strong-acid swelling protocol that effectively activates and relaxes the PBI membrane framework, leading to a marked boost in proton conduction. Integrating theoretical analysis with comprehensive characterization, the results show a dramatic performance leap over pristine PBI, with proton conductivity soaring from 1.93 mS cm⁻¹ to 50.00 mS cm⁻¹—an increase exceeding 2,590 %.

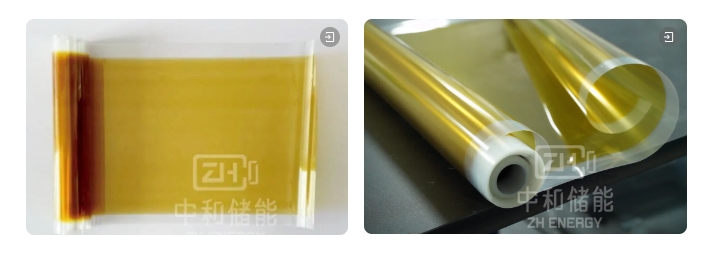

The resulting non-fluorinated ion-exchange membrane family has already entered pilot-scale production, delivering an energy efficiency ≥ 80 % at 200 mA cm⁻². Commercial products—PBI flow-battery membranes and PBI fuel-cell membranes—cover flow batteries, fuel cells, hydrogen technologies and metal-ion separation. A 60 cm-wide roll is on the market and has been repeatedly purchased by domestic and overseas universities and research institutes, confirming its superior engineering applicability and market competitiveness.

In this study, the ZH Energy–Central South University team (Prof. Su-Qin Liu) propose a high-concentration strong-acid swelling protocol that effectively activates the PBI framework and markedly enhances proton conduction. Combining theoretical analysis with experimental characterization, we demonstrate that acid-swollen PBI membranes accelerate the Grotthuss mechanism through structural optimization. The influence of post-treatment acid parameters on activation is also elucidated. For the HCOOH-PBI sample, proton conductivity jumps from 1.93 mS cm⁻¹ to 50.00 mS cm⁻¹ (> 2590 % increase). When assembled into a VRFB, the membrane achieves 76.4 % energy efficiency at 200 mA cm⁻², on par with commercial Nafion 212. The simple, low-cost swelling strategy provides a highly promising modification route for the field.

Mechanistic breakthrough: The first systematic elucidation of the acid-swelling mechanism shows that strong acids (pKa ≤ 4.76, e.g., formic acid) switch PBI–PBI interactions to PBI–acid–PBI bridges, whereas weak acids fail. Swelling degree scales with acid concentration, and an optimum (e.g., 50 mol % formic acid) maximizes conductivity without dissolution.

Industrial edge: The procedure is simple, low-cost, storage-friendly and enables uniform swelling for large-area membranes, cutting application costs. Taking HCOOH-PBI as an example, the strategy overcomes the industrial bottleneck of non-fluorinated membranes, delivering a 2590 % conductivity increase and 76.4 % VRFB energy efficiency, matching Nafion 212.

Experimental characterization: Wide-angle X-ray diffraction (WAXD) for d-spacing, FT-IR for chemical bonding, SEM for morphology, water contact angle for hydrophilicity, and ion uptake capacity (IUC) measurements.

Performance testing: Static tests—proton conductivity, swelling ratio, liquid uptake, vanadium permeability; dynamic tests—VRFB assembly to assess coulombic efficiency, energy efficiency and cycling stability.

Acid treatment protocol: Ten representative acids (formic, phosphoric, sulfuric, etc.) at 10–100 mol % were screened; formic acid was emphasized owing to its small molecular size and superior penetration.

Acid concentration gradient: Formic acid 0–100 mol %; proton conductivity, swelling ratio and liquid uptake were measured to identify the optimum (50 mol % aqueous formic acid).

Solvent comparison: Parallel experiments with HCOOH–H₂O vs HCOOH–DMF verified that acidic species, not water, are the key factor.

Structural verification: WAXD for d-spacing, FT-IR for imidazole protonation (broad 3000–3500 cm⁻¹ peak), SEM for surface/cross-section morphology, ensuring homogeneous swelling.

Performance evaluation: Static—proton conductivity (EIS), vanadium permeability (diffusion cell), contact angle (sessile drop). Dynamic—VRFB tests at 50–300 mA cm⁻², 300-cycle durability.

Theoretical validation: CNF and MSD from simulations were compared with experimental data to confirm the swelling mechanism.

Structural changes: WAXD shows d-spacing expansion from 4.00 Å to 5.20 Å; SEM confirms a dense, pore-free surface; FT-IR evidences imidazole protonation; IUC increases from 2.33 mmol g⁻¹ to 26.20 mmol g⁻¹, strengthening the protonated bridges.

Static performance: HCOOH-PBI exhibits vanadium permeability of 5.55 × 10⁻⁸ cm² min⁻¹, lower than Nafion 212 (2.68 × 10⁻⁷ cm² min⁻¹); contact angle drops from 83.5° to 63.0°, enhancing wettability. After 50 days in VO₂⁺, mass retention is 98.34 %, demonstrating high chemical stability.

Dynamic performance: In a VRFB at 200 mA cm⁻², coulombic efficiency > 98.7 %, energy efficiency 76.4 % (Nafion 212: 76.1 %). Cycling shows low capacity fade; peak discharge power density reaches 0.68 W cm⁻² (Nafion 212: 0.71 W cm⁻²), confirming industrial viability.

Figure 1 Concentration–Performance Relationship

This figure systematically presents the core concept and preliminary efficacy of the acid-swelling strategy.

- Fig. 1a illustrates the acid-treatment protocol: highly concentrated strong acid penetrates the inter-chain space of PBI, forming acid bridges that induce swelling and activate Grotthuss-type proton transport.

- Fig. 1b correlates the attainable concentration of ten acids with the resulting proton conductivity of the derived PBI membranes. Strong acids (pKa ≤ 4.76) deliver pronounced improvements at high concentration, whereas weak acids (e.g., acetic) remain ineffective; formic acid, owing to its small molecular size, ranks second only to phosphoric.

- Fig. 1c focuses on the formic-acid concentration gradient: proton conductivity, swelling ratio, and liquid uptake all rise with increasing acid concentration, confirming a positive correlation between acid concentration and swelling effect.

- Fig. 1d establishes a linear relationship between swelling ratio and proton conductivity across multiple acid solutions, verifying that swelling is the dominant factor in proton-conduction optimization. Collectively, Figure 1 provides the experimental foundation for the acid-swelling strategy and underscores the pivotal roles of acid type and concentration.

Figure 2 Dissolution Mechanism & Molecular Simulations → Revealing controllability of acid swelling and preventing membrane dissolution during production

- Fig. 2a compares HCOOH–DMF and HCOOH–water systems: at 80 mol % formic acid, the DMF system still induces swelling and raises conductivity, proving that the acidic species—not water—is the key factor; at low concentration (10 mol %), the DMF system produces a gel state, highlighting the role of solvent–non-solvent balance.

- Fig. 2b schematically contrasts PBI dissolution mechanisms: in strong-acid solvents, acid bridges connect PBI chains (Mechanism 2), whereas highly polar aprotic solvents directly attack the chains (Mechanism 1), explaining the threshold difference between swelling and dissolution.

- Figs 2c–e present CNF-based kinetic analyses: as formic-acid concentration rises, the restriction of acid molecules by water weakens (CNF decreases); 50 mol % is the optimum (CNF ≈ 1), beyond which membrane dissolution occurs. The CNF for formic acid around PBI remains stable, indicating a concentration-dependent swelling effect.

- Fig. 2f employs MSD curves for theoretical validation: proton displacement in HCOOH-PBI far exceeds that in pristine PBI; the theoretical conductivity (46.20 mS cm⁻¹) closely matches the experimental value (50.00 mS cm⁻¹), confirming Grotthuss-dominated performance enhancement.

Figure 3 Structural Characterization → Demonstrating uniform swelling to guarantee batch-to-batch consistency in scaled production

- Fig. 3a shows that HCOOH-PBI is transparent (swelling ratio 28.77 %), in contrast to the opaque porous membrane (E-PBI), indicating uniform swelling without pores.

- Fig. 3b SEM images confirm smooth and dense surface and cross-section morphologies identical to pristine PBI, ruling out heterogeneous structures.

- Fig. 3c WAXD patterns exhibit a peak shift from 21.3° to a broad 17.0°–22.4° peak; Bragg’s law yields an increase in d-spacing from 4.00 Å to 5.20 Å, in excellent agreement with the theoretical model (5.26 Å) and the experimental swelling ratio (28.77 %).

- Fig. 3d schematically depicts the acid-bridge mechanism: the expanded chain spacing (< 8.5 Å) ensures that only the Grotthuss mechanism is operative. These results collectively demonstrate that acid swelling uniformly enlarges chain spacing to optimize proton transport.

Figure 4 Vanadium-blocking & Hydrophilicity → Satisfying long-cycle VRFB requirements (>300 cycles, Figs 5b,c)

This figure analyzes chemical bonding and static performance.

- Fig. 4a FT-IR spectra show peak broadening in the 3000–3500 cm⁻¹ region for HCOOH-PBI, indicating imidazole-ring protonation and strengthened hydrogen bonding.

- Fig. 4b IUC comparison (HCOOH-PBI: 26.20 mmol g⁻¹ vs. pristine PBI: 2.33 mmol g⁻¹) confirms enhanced ion adsorption via acid bridges.

- Fig. 4c vanadium permeation tests reveal a rate of 5.55 × 10⁻⁸ cm² min⁻¹ for HCOOH-PBI—lower than Nafion 212 (2.68 × 10⁻⁷ cm² min⁻¹)—benefiting from the expanded yet still selective d-spacing (5.20 Å < vanadium ion size 5.39 Å) and Donnan exclusion.

- Fig. 4d contact angle decreases from 83.5° to 63.0°, evidencing improved hydrophilicity arising from protonation-enhanced hydrogen bonding with water. These results highlight that acid swelling simultaneously optimizes proton conduction and maintains high selectivity.

Figure 5 Cell Performance → Matching perfluorinated membranes at 50 % lower cost

This figure presents VRFB performance to validate industrial potential.

- Fig. 5a shows that HCOOH-PBI-based VRFBs achieve > 98.7 % coulombic efficiency across all current densities and 76.4 % energy efficiency at 200 mA cm⁻², rivaling Nafion 212 (76.1 %), while pristine PBI fails at high current density.

- Figs 5b–c cycling tests (300 cycles, 200 mA cm⁻²) demonstrate lower capacity fade and stable voltage efficiency for HCOOH-PBI compared with Nafion 212, attesting to superior durability.

- Fig. 5d power-density curves yield a peak discharge value of 0.68 W cm⁻², approaching that of Nafion 212 (0.71 W cm⁻²), underscoring commercial viability.

In summary, the acid-swelling strategy is not only simpler and more effective than conventional modifications (e.g., pore introduction or polymer grafting) but also imposes lower storage and transport requirements. Moreover, the pronounced swelling allows the polymer to be processed into larger-area membranes, further reducing application costs. This study systematically investigates how membrane structure, acid speciation, and acid–membrane interactions influence proton conductivity during acid activation, and proposes a facile yet powerful acid-swelling strategy applicable to VRFBs and related fields.

Product Series: