Economic Model Analysis of an Integrated VRB-Electrolysis Hydrogen Production System

Classification:Industrial News

- Author:ZH Energy

- Release time:Jun-04-2025

【 Summary 】ZH Energy NeLCOS Energy Storage Cost Calculator, calculating the return on investment of your energy storage system for free.

A certain non-ferrous metal mining, selection, smelting, and deep processing integrated enterprise in Shaanxi Province has already built and put into operation a 500 Nm³/h electrolysis water hydrogen production facility in its plant area. To ensure the continuous and safe operation of hydrogen production and reduce the high peak-valley electricity cost, the enterprise plans to configure a vanadium redox flow battery energy storage system, considering both safety and economic efficiency.

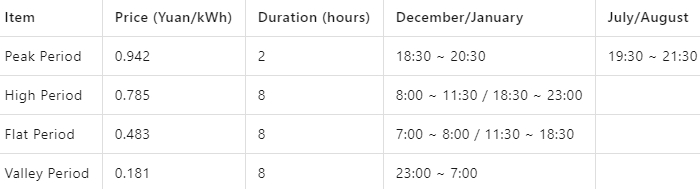

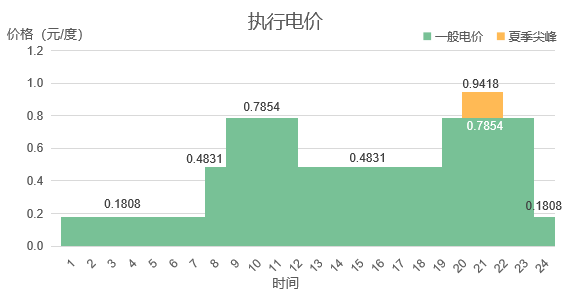

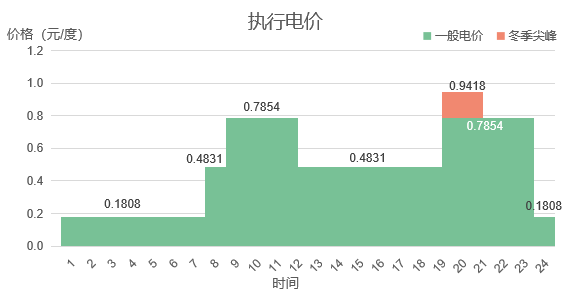

According to the agency electricity purchase prices in Shaanxi Province, the peak-valley electricity price difference is 0.6046 yuan per kWh, and the peak-valley price difference in January, July, August, and December reaches 0.761 yuan per kWh. The electricity price structure is shown in the figure below:

The customer originally planned to use an 8-hour energy storage system. Based on the electricity consumption analysis, the peak, flat, and valley periods are all 8 hours each. Following the principles of covering the peak period and fully charging during the valley period, the system is designed to utilize the 8-hour valley period for charging. Since the system's DC efficiency is 80%, the charging time = 8 ÷ 80% = 10 hours. This means that in addition to using the entire valley period for charging, an additional 2 hours of charging is required during the flat period to meet the 8-hour discharge requirement. The economic benefit of charging during the flat period and discharging during the peak period is minimal. Therefore, the additional investment for a 2-hour capacity is not cost-effective. The discharge time = 8 × 80% = 6.4 hours. Thus, a 6-hour energy storage system can be used to achieve 1.33 cycles per day (8 hours) to obtain higher economic efficiency.

The investment structure is as follows: the owner contributes 20%, and the remaining 80% is financed through a loan. The loan is repaid in equal monthly installments over 20 years with an annual interest rate of 2.50%. In terms of profit distribution, neither the owner's share nor government preferential policies have been calculated. In cost accounting, design and civil construction costs are not included, and the equipment is depreciated over 20 years. The value-added tax rate for the equipment is 13%, and the income tax rate is 25%. The annual operation and maintenance cost is calculated as 0.8% of the equipment cost, and the shutdown maintenance rate is 4%. At the end of the 20-year service life of the vanadium redox flow battery system, the recovery rate of the electrolyte can reach 70%, and the recovered funds will be included in the revenue of the last year.

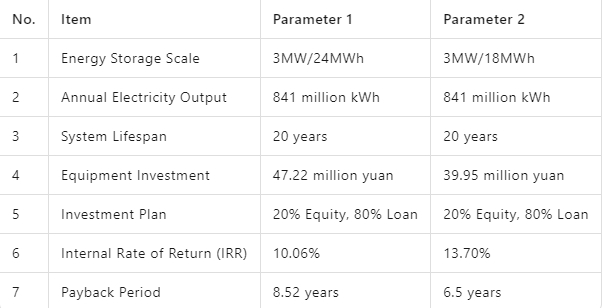

Based on the above operational analysis, the economic data of the project was obtained through the NeLCOS® Energy Storage Calculator independently developed and operated by ZH Energy:

The NeLCOS® Energy Storage Calculator independently developed and operated by ZH Energy can provide accurate and quick generation of investment return rates for energy storage systems from the perspectives of the full-life cost per kWh, annual investment return rate, and energy storage configuration plans, free of charge for energy storage customers and investors. To use it for free, visit the ZH Energy official website (www.z-henergy.com) or scan the QR code.(https://nelcos.z-henergy.com/)

Product Series: