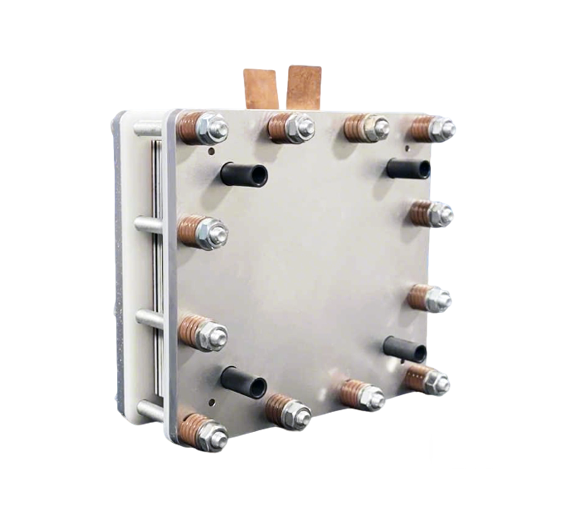

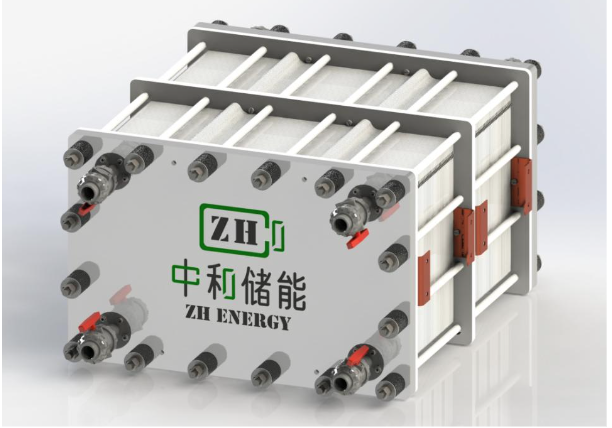

Flow Battery Stack

PRODUCT OVERVIEW

The stack is the core component of the flow battery energy storage system. It is the place where electrochemical reactions of the electrolyte occur to achieve charging and discharging, and it determines the power of the energy storage system. Because the flow battery stores the electrolyte outside the reaction stack, it has the characteristic of power-capacity decoupling: the stack determines the power of the battery, and the amount of electrolyte determines the capacity of the battery. Relying on the founder's more than ten years of industrialization experience in the American flow battery industry, ZH Energy has developed and produced stacks with an internationally leading level, providing strong technical support for the product to achieve a stable and efficient operation with a service life of 20 years. The stack product has obtained UL 1973 and IEC 62932 certificates, meeting the grid-connection requirements for most countries worldwide.

PRODUCT FEATURES

High performance: The flow channel has been fully optimized and verified through engineering. With a power density of 200 mW/cm2, the energy efficiency is > 80%.

Good consistency: Produced on a mechanized production line, the standardized production process has obtained the ISO9001 international Quality Management System certification.

Excellent appearance design: The components are exquisitely designed, the assembly process is stable, and the end plate spray painting can be customized, making it suitable for showcase.

SPECIFICATION

Products include: end plate, current collector, liquid flow frame, bipolar plate, proton exchange membrane, graphite felt electrode, etc.

| Specification Parameter | |||

|---|---|---|---|

| Rated Power | 100W | 1KW | |

| Voltage Range | 4-8V | 10-16V | |

| Max. Current | 18A | 112A | |

| No. of Cells | 5 | 10 | |

| Energy Efficiency | DC≥80% | ||

| Stack Dimensions | 20cm×22cm×14cm | 28cm×50cm×35cm | |

| Stack Weight | 5kg | 46kg | |

| Electrolyte Inlet/Outlet Size | Hose | DN20 | |

| Protective Class | IP20 | ||

| Best Operational Temperature | 20-40℃ | ||

| Environmental Humidity | 5-95% | ||

Product includes: end plates, current collectors, flow frames, bipolar plates, membranes, electrodes.

Test conditions: Ambient temperature: 25-30℃. Initial electrolyte: 1.7M V3.5+, 4.2M SO4 in both positive and negative tanks.

Pre-test procedure: Circulate electrolyte for 24 hours to fully wet stack materials, then activate stack with 3 charge-discharge cycles at 50% rated power (2.5kW / 16kW).

Formal test: Perform charge-discharge cycles at constant 5kW / 32kW power. Charge/discharge cutoff voltages refer to technical specification table.

| Specification Parameter | |||

|---|---|---|---|

| Rated Power | 5KW | 32KW | |

| Voltage Range | 50-80V | 88-140V | |

| Max. Current | 112A | 360A | |

| No. of Cells | 50 | 88 | |

| Flow rate of catholyte or anolyte | 25-30L/min ( Each flow inlet 12.5-15L/min) | 100-120L/min ( Each flow inlet 50-60L/min) | |

| Pressure drop through stack | 60-80kPa | 120-150kPa | |

| Energy Efficiency | DC≥80% | ||

| Stack Dimensions | 660mm×504mm×351mm(L*W*H) | 1210mm×839mm×545mm(L*W*H) | |

| Stack Weight | 94kg | 350kg | |

| Electrolyte Inlet/Outlet Size | DN20 | DN25 | |

| Protective Class | IP20 | ||

| Best Operational Temperature | 10-30℃ | ||

| Environmental Humidity | 5-95% | ||

OBTAINED CERTIFICATES