From Lab to Industrialization: R&D Data Drives the Implementation of Flow Battery Technology

Classification:Company News

- Author:ZH Energy

- Release time:Sep-15-2025

【 Summary 】In 2025, the global flow battery market witnessed explosive growth, with China's all-vanadium flow batteries (AVFBs) continuing to lead the world with a global market share of over 60%.

In 2025, the global flow battery market witnessed explosive growth, with China's vanadium redox flow batteries (VRFB) continuing to lead the world with a global market share of over 60%. Emerging technology routes such as iron-chromium (Fe-Cr), zinc-bromine (Zn-Br), zinc-iron (Zn-Fe), and sulfur-iron (S-Fe) flow batteries are maturing at an accelerated pace, driving the industry toward a new pattern of diversified and coordinated development. Key breakthroughs have been achieved in cost advantages and technical indicators across multiple mainstream technology directions:

● The material cost of zinc-bromine flow batteries is only 20%-30% of that of lithium-ion batteries;

● The initial installation cost of sulfur-iron flow batteries is expected to drop below 1 yuan per watt-hour (¥1/W·h), with the full-lifecycle levelized cost of electricity (LCOE) as low as 0.1 yuan per kilowatt-hour (¥0.1/kWh);

● The proton conductivity of the PBI membrane developed by Central South University has increased by 26 times, whose performance surpasses that of traditional perfluorinated membranes;

● An innovative achievement by the Chinese Academy of Sciences (CAS) has improved the conversion efficiency of all-vanadium flow batteries by 10% under a high current density of 400 mA/cm².

In this round of technological revolution, high-throughput experiments and data-driven research and development (R&D) have become key driving forces. Centering on the entire R&D process of flow batteries, ZH Energy provides a complete testing solution ranging from material screening to system verification, offering solid support for scientific research innovation and industrialization.

Single Cell System: Focusing on Intrinsic Material Properties

Positioning: The starting point of R&D, used for basic material screening and mechanism research.

Functions: Under a simple and controllable environment, it accurately evaluates the intrinsic properties (such as cycle life, Coulombic efficiency, and selectivity) of new electrolytes, membranes, and electrode materials, eliminates other interfering factors, and provides the most direct and rapid feedback for material optimization.

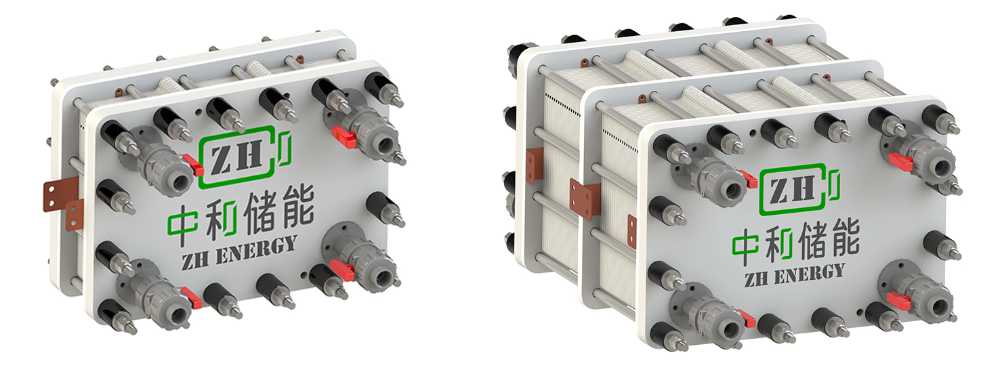

3W, 20W, 100W Single-cell Systems

Test Stack: Verifying the Feasibility of Engineering Scaling

Positioning: A key bridge from materials to systems, focusing on engineering issues.

Functions: It evaluates the performance of materials after scaled-up assembly, identifies engineering-level problems (such as the uniformity of flow field design, the consistency of individual cells, and sealing reliability). Its core is to test the compatibility and stability of materials and structures in a multi-cell environment, thereby reducing risks for pilot-scale trials.

1kW, 5kW, 32kW Test Stacks

Test System: Evaluating System Integration and Commercial Value

Positioning: The final simulation verification before industrialization, focusing on the overall system performance.

Functions: Under working conditions that are infinitely close to real-world scenarios, it tests the comprehensive performance (energy efficiency, power consumption, energy density) and long-term operational reliability of the complete system (including pipelines, pumps, thermal management, and control units). Its core is to verify the commercial indicators of the technology and provide a decision-making basis for large-scale applications.

1-5kW/2h, 10-50kW/2h, Customizable on demand

Facing R&D challenges, ZH Energy full-stack testing solution (from single cell → stack → system) comprehensively improves the R&D efficiency and certainty from basic material innovation to final system integration by providing accurate and reliable data. It offers the strongest support for material application, technical route selection, and commercial implementation.

ZH Energy Lab-series testing solutions have been sold to over 10 countries, including China, the United States, the United Kingdom, Italy, and Canada. The products have received wide acclaim from customers and achieved multiple batches of repeat purchases.

The test systems have been successfully delivered to manufacturers, universities, and research institutions in the field of flow batteries such as all-vanadium, iron-chromium, all-iron, and organic flow batteries. They are widely used in testing scenarios including membrane materials, electrolytes, electrodes, BMS (Battery Management System), stacks, and systems, and are highly recognized by customers. For more testing needs related to different flow battery technology routes, please feel free to consult us for customized solutions.