High-Throughput Experiments: An Efficiency Revolution in Flow Battery Research

Classification:Company News

- Author:ZH Energy

- Release time:Dec-10-2025

【 Summary 】The triple advantages of efficiency, comparability and automation make high-throughput the key experimental paradigm.

Against the backdrop of accelerating global energy transition, flow batteries are emerging as a critical technology route for long-duration energy storage. With the expansion of material systems, evolution of electrochemical structures, and increase in operating condition variables, large-scale parameter combination testing and comparison are required within limited timeframes—whether for electrolyte system screening, membrane/electrode material iteration, or flow field structure optimization. This presents a common challenge for research work: experimental scale and variables continue to grow, while traditional single-channel, sequential experimental models can no longer support the fast-paced R&D cycle.

Against this backdrop, the advantages of high-throughput experiments have become increasingly prominent. Its value is mainly reflected in three aspects: first, parallel testing enables a multiple increase in the number of experiments conducted within the same time window; second, multi-channel testing under identical conditions significantly reduces errors caused by environmental and operational variations, making data more comparable; third, integrated with automated flow control, temperature regulation and data acquisition systems, high-throughput experiments cut down labor input and consumable waste, allowing researchers to focus more on experimental design and result analysis.

From the perspective of actual research needs, a high-quality high-throughput testing platform should possess several core capabilities: sufficient parallelism to support simultaneous testing of multiple material groups; stable, controllable and reproducible experimental conditions; a complete data chain for capturing key metrics such as EE, CE, capacity and decay trends; and compatibility with diverse material systems and operating conditions, enabling seamless scaling from small-area exploratory tests to large-area validation trials.

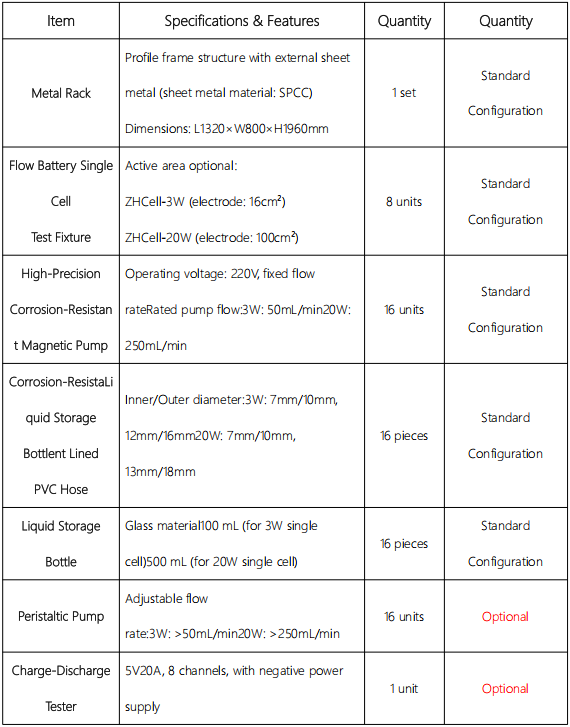

In response to the demand for these capabilities in flow battery research, ZH Energy has developed a multichannel flow battery single cell test bench tailored for scientific research scenarios. As a technology R&D enterprise with years of experience in flow batteries, ZH Energy operates a full-chain experimental testing cluster covering materials, stacks and systems. This gives the company a direct understanding of pain points in the research process, the complexity of variables and requirements for data consistency. Therefore, the equipment design places greater emphasis on true comparability between channels, stable system operation and broad adaptability to different experimental scenarios.

The multichannel flow battery single cell test bench (8 channels as standard, with 3 or 6 channels optional) is specifically designed for flow battery research. It enables simultaneous parallel comparative experiments on electrolytes, membranes, electrodes or flow field structures, and integrates data acquisition and analysis functions, providing researchers with systematic and scalable high-throughput testing capabilities.

In today’s increasingly competitive landscape of battery research, high-throughput experiments have become a key driver for enhancing R&D efficiency, while reliable testing equipment serves as the foundational infrastructure to support this methodology. With the advantages of parallel testing, precise data acquisition and high adaptability, ZH Energy Multichannel Flow Battery Single Cell Test Bench helps research teams complete material screening and structural optimization more efficiently, accelerates the verification and commercialization of research outcomes, and drives the continuous advancement of long-duration energy storage technologies.

For more details, please scan the QR code to get in touch with ZH Energy.